From father to son

History

Sugar beet gained recognition in France in the 19th century, definitively replacing sugar cane which had been its major sweet rival for more than 3,000 years. In 1812, Benjamin Delessert succeeded in making large quantities of sugarloaves and he was the first to present them to the Emperor Napoleon. Full of enthusiasm, the Emperor issued 500 production licences and ordered the plantation of several thousands of hectares of beet. The great sugar beet adventure was underway. It was to be half a century before the Souppes sugar refinery was built.

Birth of the Souppes sugar refinery

In 1873, Félix Ouvré, a forestry operator and owner of the Chancepoix estate, decided to launch the first sugar refinery on his own land in the province of Gâtinais. This was to mark the start of an exceptional entrepreneurial adventure. Six generations from father to son, have since followed in his footsteps, ensuring that the company has continued to thrive and develop. The Souppes sugar refinery is now the only one of its kind among French sugar refineries. The family owns the majority of the capital and manages the company.

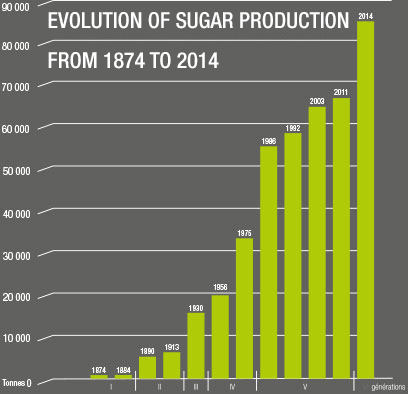

Changes in production

Through exemplary management of an industrial legacy, each generation has made their own contribution to the business, despite the many changes which have been needed.

Key

figures

- Founded in 1873

by Félix Ouvré - 6 generations

- 140 campaigns

The Souppes sugar refinery and distillery

More than a century after its creation, the company continues to play an essential role in the region, both in terms of jobs and economic resources: with a turnover of 54 million euros, around 130 permanent jobs and 40 seasonal jobs.

Félix Ouvré produced 800 tons

of sugar in 125 days

84,000 tons were produced

in 92 days

From beet to sugar

The sugar beet harvest starts at the end of September and must be completed before the hard frosts. This harvest period determines the length of the ‘sugar marketing season’, when for around three months, 24 hours a day, seven days a week, the sugar refinery will operate at full capacity. There are nine stages in the sugar production process.

The beet seeds, which are at the origin of French production, are all certified by the Groupement National Interprofessionnel des Semenciers (GNIS), which is responsible for controlling and certifying seeds under the auspices of the Ministry for Agriculture. As a result, no genetically modified beet seed is marketed in France.

Production

The harvest : sugar beet is supplied from an average distance of 25km: 67% from Seine-et-Marne, 19.2% from Loiret, 8.6 % from Yonne and 5.2% from Aube. The harvest is transported to the sugar refinery in 50 lorries. Once it arrives, the lorries are weighed and a sample of the beets are assessed for their sugar content. This average rate determines the purchase price.

Washing : the beets are transported on conveyor belts to the washing area. They are moved around by blades and are sprayed with high pressure water, removing any stones, grass and earth.

Cutting : the clean beets are then cut into thin slices known as “cossettes”.

Diffusion : the process of extracting the sugar from the beet can then begin. The cossettes are placed into huge diffusers and are rotated in one direction while hot water is circulated in the opposite direction. The water gradually becomes enriched with the sugar, leaving behind just the “pulp”.

Refining : the juice which comes out of the diffuser contains impurities and is refined through carbonatation.

Filtration : the filtration process then begins, to remove the calcium carbonate from the refining process and to obtain a clear juice.

Evaporation : the post-filtration juice contains 13% sugar and 87% water. Evaporating pans enable a syrup to be gradually obtained containing around 70% sugar.

Crystallisation : once it is in a state known as “supersaturation”, the syrup is “seeded” with very fine sugar crystals which triggers the formation of what is known as “massecuite” (from the French term for ‘cooked mass’), consisting of multiple sugar crystals suspended in a coloured syrup.

Centrifugation : the massecuite is then spun at high speed, producing a brown syrup and leaving behind the white crystallised sugar.

Drying : the hot, humid sugar is then dried and is ready to be preserved.

Storage : once dried, the sugar is kept in a silo with constant humidity until it is sold.

Quality, Safety, Environment

Quality

In 1998, the sugar refinery conducted an HACCP study and in 2004 it received its first Food Safety Management System certification.

In 2007, this continuous improvement approach led it to receive a new ISO 22000 certificate (first international food safety standard).

With a view to improving client satisfaction, in 2014 this was complemented by the PAS 220, which sets a higher level in terms of good practice: FSSC 22000. Our sugar also holds specific certifications such as Kosher and Halal.

The quality department is organised in such a way as to bring together all the parameters relating to upstream and downstream traceability within a limited time. Internal exercises take place regularly, and clients and suppliers are invited to take part in them.

In addition, the General Management and field staff are heavily involved in the quality control process, something which our clients recognise and highly appreciate.

Safety

Management and the safety team strive to constantly improve working conditions and achieve our “zero accident” objective.

Several actions have been taken to achieve this:

- Establishment of clear and precise safety procedures

- Development of a risk prevention policy and a continuous improvement approach

- Integration of safety as an essential component of the job

- Creation of a management safety system

The environment

The Souppes-sur-Loing sugar refinery is committed to respecting and preserving the quality of the environment.

It is authorised by the Agence de Bassin Seine Normandie to manage its water and reuses waste water for fertigating crops. All by-products from the sugar refining process are reused and re-purposed.

We constantly strive to save energy and manage our CO2 emissions.

Outlook

Key

figures

France :

- 8th biggest sugar producer in the world

- Biggest producer in the world of sugar beet

- Biggest sugar producer in the EU

European economic context

In 2006, the Common Organisation of the Sugar Market (COSM) was reorganised to adapt to the World Trade Organisation (WTO) regulations and to open up the European market to imports from LDCs (Less Developed Countries) and ACP countries (Africa, the Caribbean and the Pacific).

European production quotas were reduced by 30% and more than 40% of factories disappeared. The European Union, which was previously principally an exporter, has now become the world’s leading importer of sugar.

New sugar regulations from 1st October 2017. This Reform was adopted by the European Commission Council of Ministers on 26th June 2013.

The reform will abolish the quota regime on 30th September 2017. The minimum price for sugar beet will also be abolished. These two measures will make it possible, notably, for sugar manufacturers to export without being restricted by a WTO ceiling.